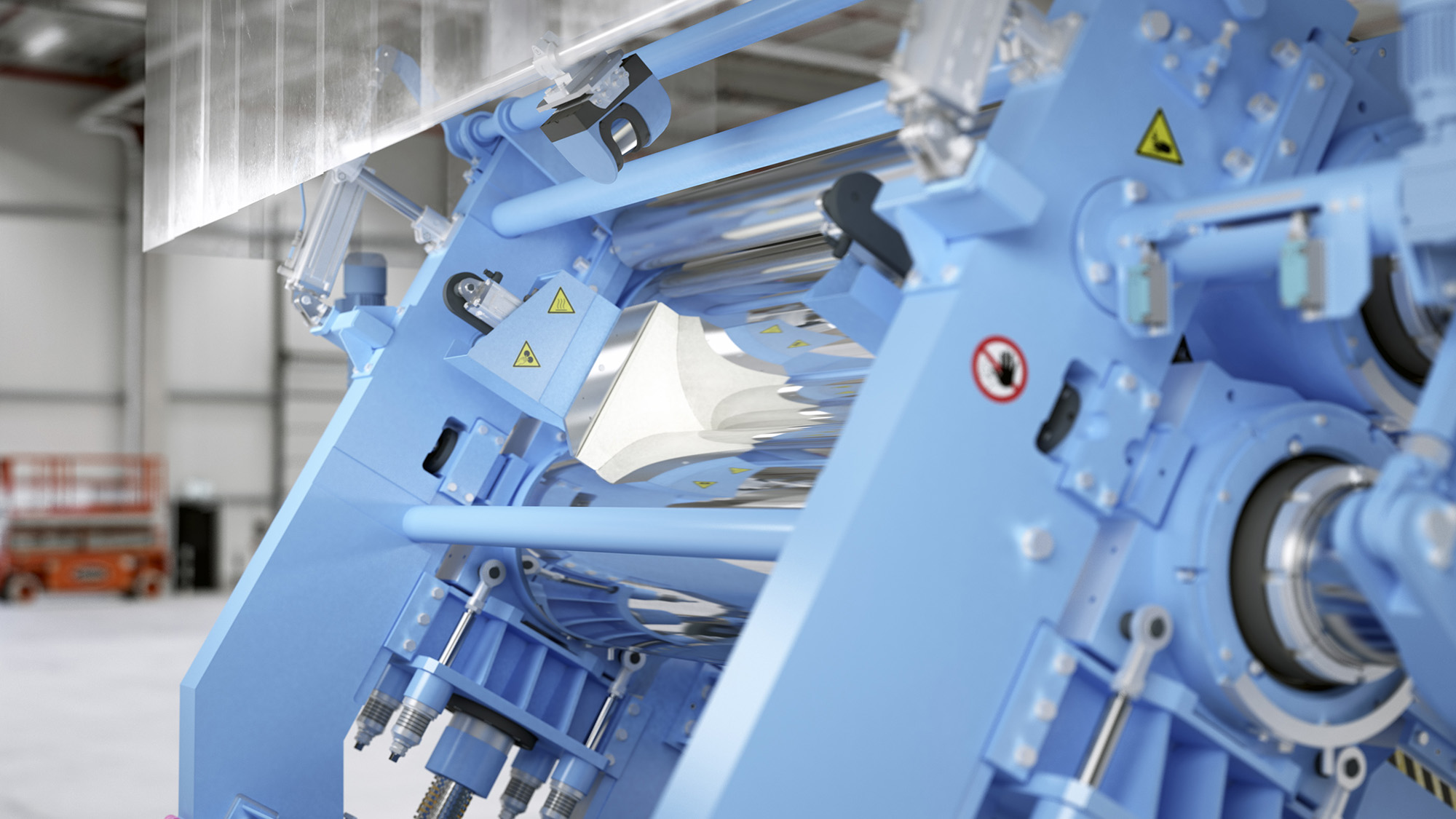

Calendering

The technology used for the KKA melt roller calenders emerged more than 55 years ago and has been continuously advanced and refined since then. In terms of mechanical and process engineering, the status quo of the MRC has been developed by KKA also on the basis of know-how from companies like "Zimmerplastic" and "Saueressig". Numerous turn-key plants delivered worldwide testify to this fact and the technology is perfectly complemented by KKA’s well-proven rotogravure printing, embossing, laminating and coating plants.