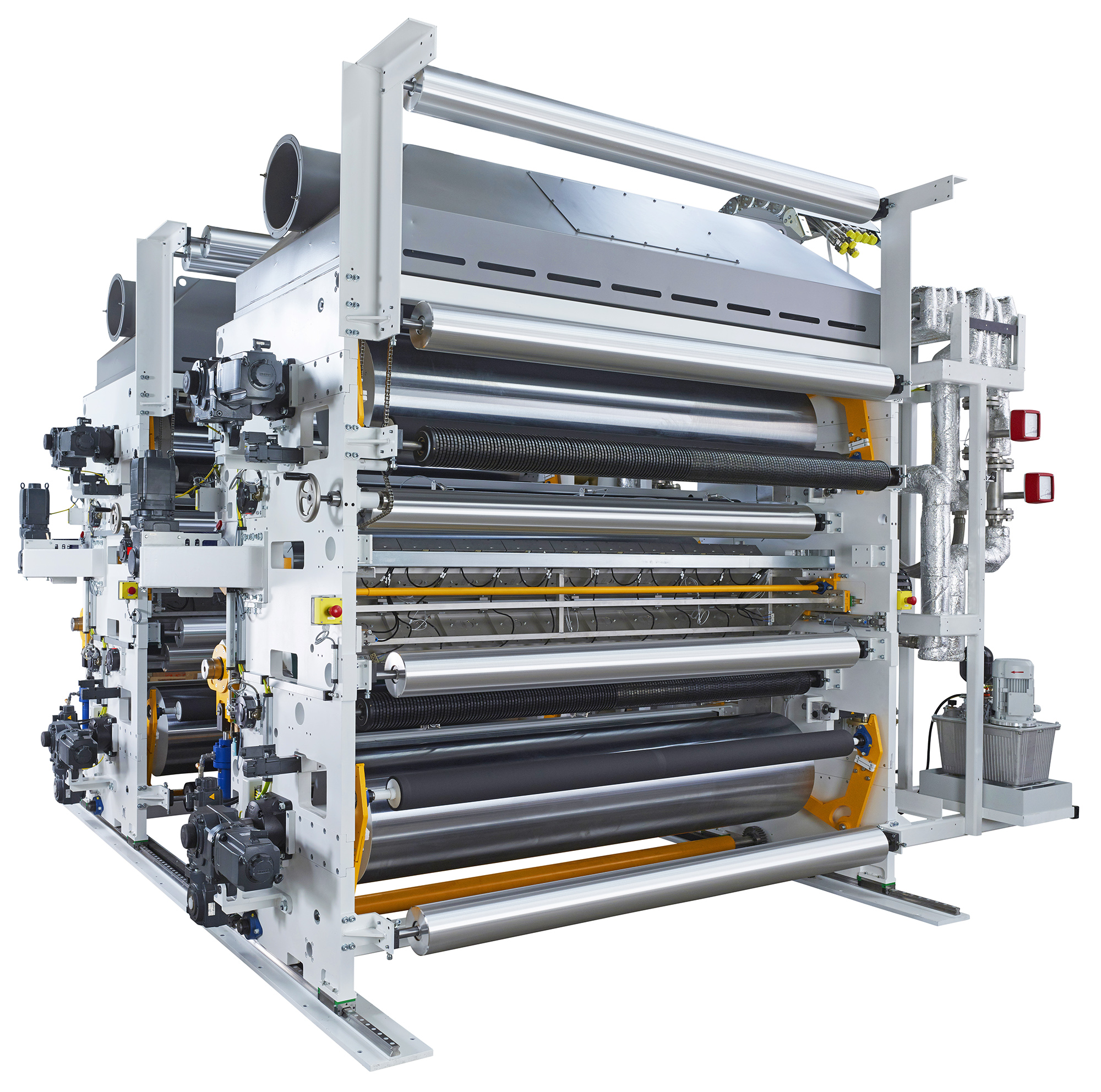

Laminated composites advantageously combine the property patterns of the substrates used. Using thermal energy and / or adhesives as well as printing, KKA laminating systems produce web-shaped multi-layer products in continuous operation, optimized in terms of high quality and used raw material and operating costs.

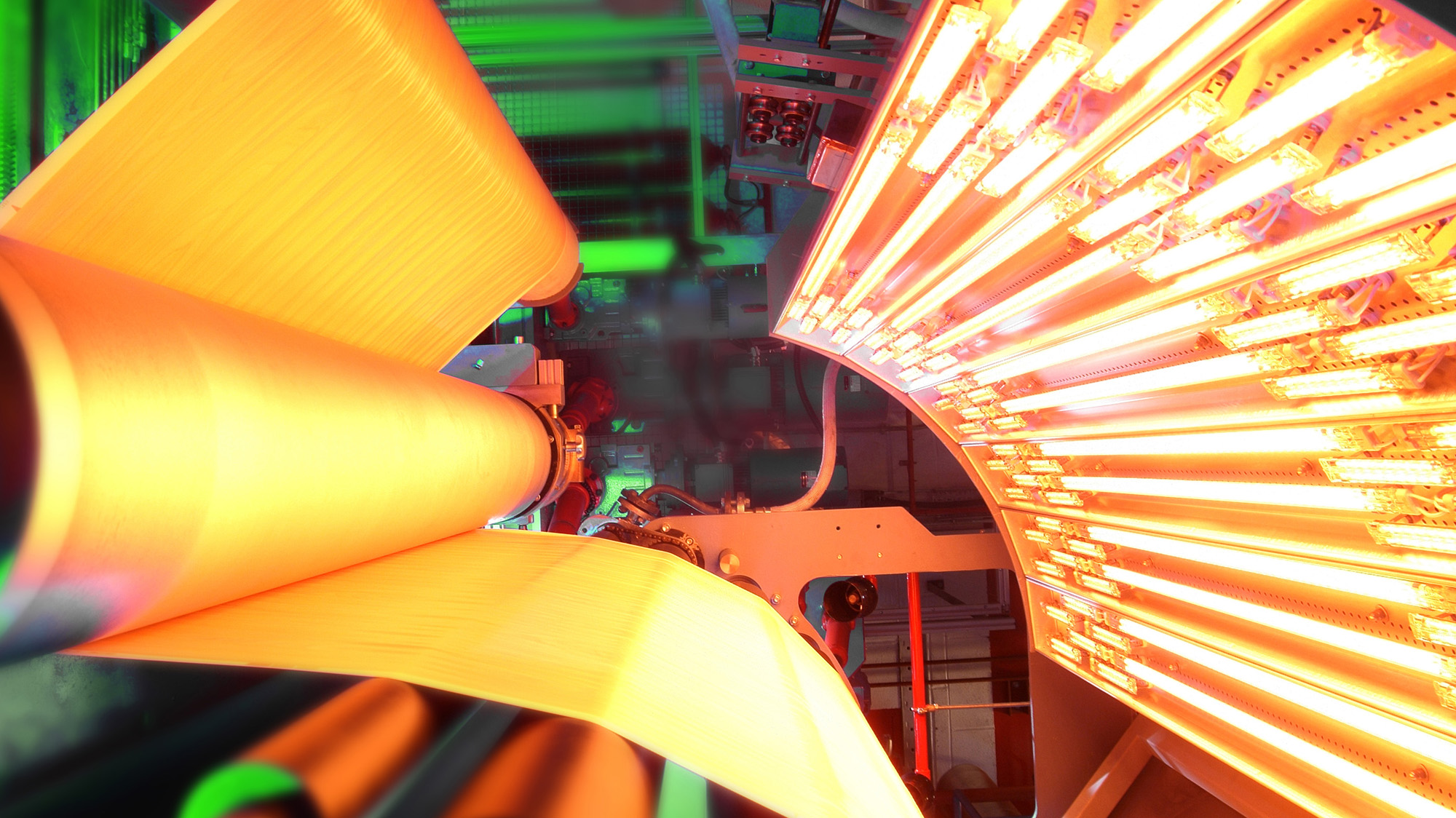

With separate embossing units already integrated in the laminating process, refinement steps are possible that give the treated substrate surfaces new properties in terms of look, feel and function. KKA embossing technology combines efficient energy transfer to the substrate with service-friendly operation / changing the embossing tools. Requirements for the end products in use as automotive interior and decorative films are met to the

KKA Laminating and embossing plants guarantee efficient production and continuously high product quality at the same time. Here the scope of processing possibilities for film thicknesses ranging from 0.01 to 1 mm, and up to 15 mm in the case of foam and laminated film, is extraordinarily high.