Printing & Gravure Coating

From the variety of rotogravure printing applications for finishing the surfaces of web type material, KKA has chosen to concentrate on flexible floor coverings and furniture film decoration with its rotogravure printing unit programme. Whether an inline or offline configuration is used, the equipment is part of the fully integrated technology provided by KKA to manufacture marketable films from raw material to finished product.

In terms of sustainability and ecological aspects, KKA gravure coating units guarantee an efficient surface functionalisation of web type substrates. Direct or indirect application technologies are used to create surface finishings with not only optical or haptic effects but also dirt-repellent or high-barrier properties. KKA offers turn-key solutions that not only include all production steps from the unwinder to the finished roll but also the necessary drying and crosslinking processes.

KKA rotogravure printing and gravure coating units are suitable for use with various materials such as film – without or without carrier like fabric, knitted fabric, nonwoven substrates and paper.

Rotogravure Printing

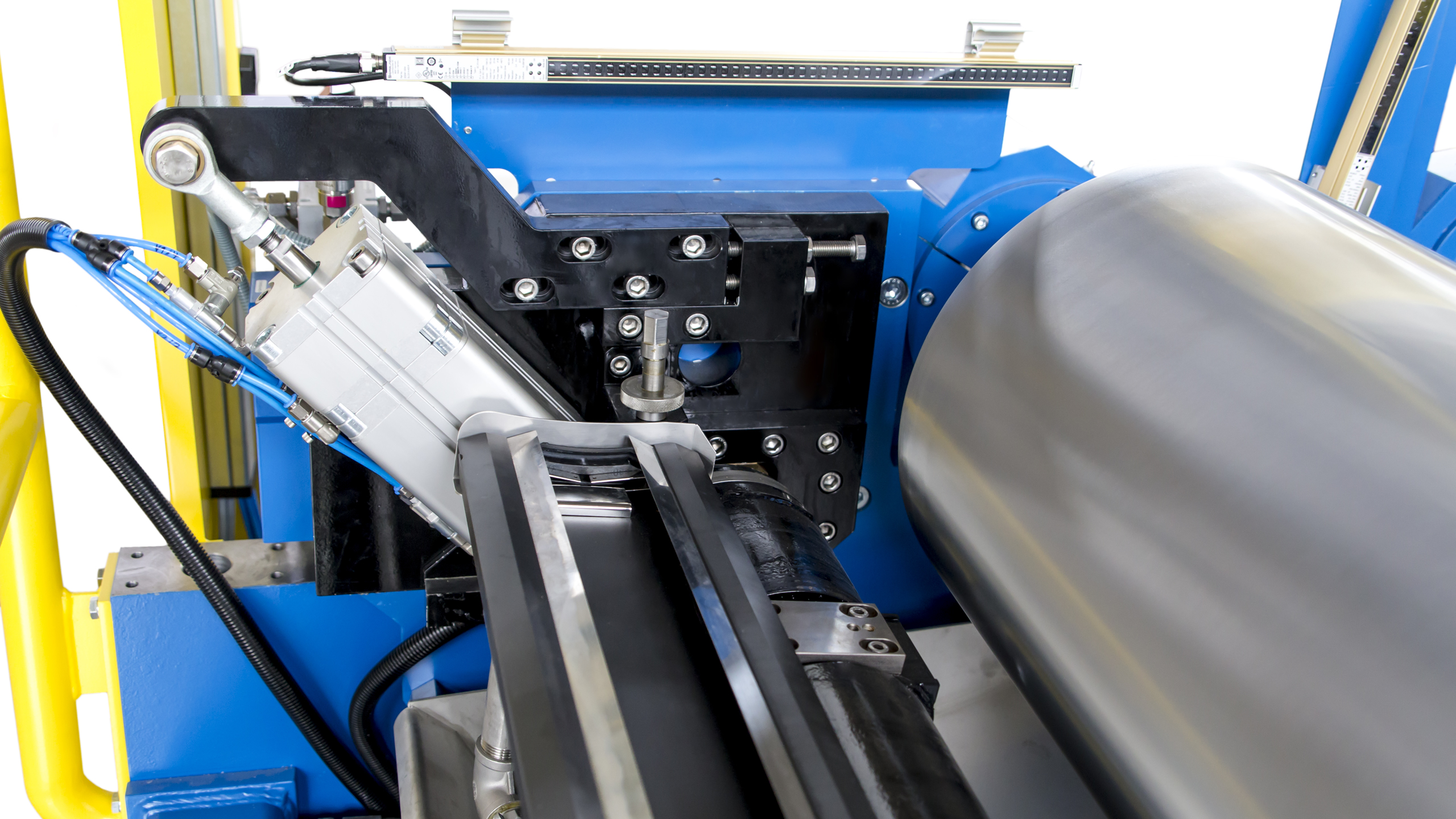

KKA rotogravure printing plants with their high-precision register control system guarantee ultimate product quality. They stand out due to their perfect reliability as well as their easy operation and maintenance.

Gravure Coating

Experience and know-how in the design and execution of high-quality machine technology are reflected in the KKA Gravure Coating Lines. The structural design is consistently oriented towards the requirements of the used lacquer and the properties of the finished product.