Company

The medium-sized family business KKA has its origins in 1862 and has been based since 2011 in the greater Leipzig area. Quality, reliability and participation in dealing with customers and in the projects characterize the essence of KKA – Kleinewefers Kunststoffanlagen as well as the other companies and partners of the corporate family. We pursue this approach to the outside and also to the inside. This is evident in the long-term cooperation with customers as well as the long affiliation of our 70 first-class trained and motivated employees. It is above all skilled workers, masters, technicians, engineers and doctors. Their loyalty to the company is of real value. After all, many years of experience, well-rehearsed processes and short distances are the keys to smoothly running Projects.

Plant Construction is

our Core Competence.

Organization

The date of production start-up is a milestone within a business plan, in order to generate sales volume by supplying the contractedproduct quantities and qualities as planned. Therefore an absolutely reliable implementation of the scheduled project is a must.

KKA is using its full capacity to do exactly that. Experienced project managers and highly motivated Teams help us to drastically cut production, installation and start-up time, thus ensuring you early returns on your investment.

History

1862

Johann Kleinewefers was the founder of the company Joh. Kleinewefers Söhne in Krefeld. At the time, business activities were divided into a machine factory for all types of calenders, an iron foundry and a roller engraving establishment.

1974

On 1st October 1974 the company Ramisch Kleinewefers GmbH was founded with the aim to merge the two competing product ranges of Dr. Ramisch & Co. Maschinenbau and Kleinewefers GmbH.

1977

The companies Briem and Dornbusch were taken over by Ramisch Kleinewefers GmbH in 1977, followed by Zimmer Plastic in 1979, while the product range of the company Deck was integrated in 1980.

1986

In 1986 contracts were signed to take over Kleinewefers Textilmaschinen GmbH and the US based Greenville Machinery Corporation.

1991

Having decided to leave the company of his own accord, Mr. R. Ramisch sold his Ramisch Kleinewefers GmbH shares to Kleinewefers Beteiligungs GmbH on 31st March 1991. The companies Babcock Krauss Maffei and Kraftanlagen Heidelberg were incorporated into Ramisch Kleinewefers GmbH in 1991.

1996

In 1996 Kleinewefers took over Saueressig’s melt roller product range.

2001

As a result of the merger between Kleinewefers Kunststoffanlagen and Kleinewefers Textilmaschinen, Kleinewefers Anlagen GmbH was created in 2001. With effect from 1st October 2003, the plastics machinery division of Kleinewefers was integrated into Kampf GmbH & Co. Maschinenfabrik by way of an asset deal.

2008

As from 1st January 2009, the Meerbusch division for finishing technology whose activities include coating, printing, laminating and embossing plants and components as well as calender lines with up to three calender rollers is now under new ownership after having been sold by Kampf to KKA GmbH.

2011

On 1st April 2011 KKA GmbH Kleinewefers Kunststoffanlagen moved from its Meerbusch facilities into their new premises at the company headquarters in Weissandt-Gölzau.

Join the Team

Please get an overview of our vacancies with the following list. For more information go to the respective job description.

Team Work

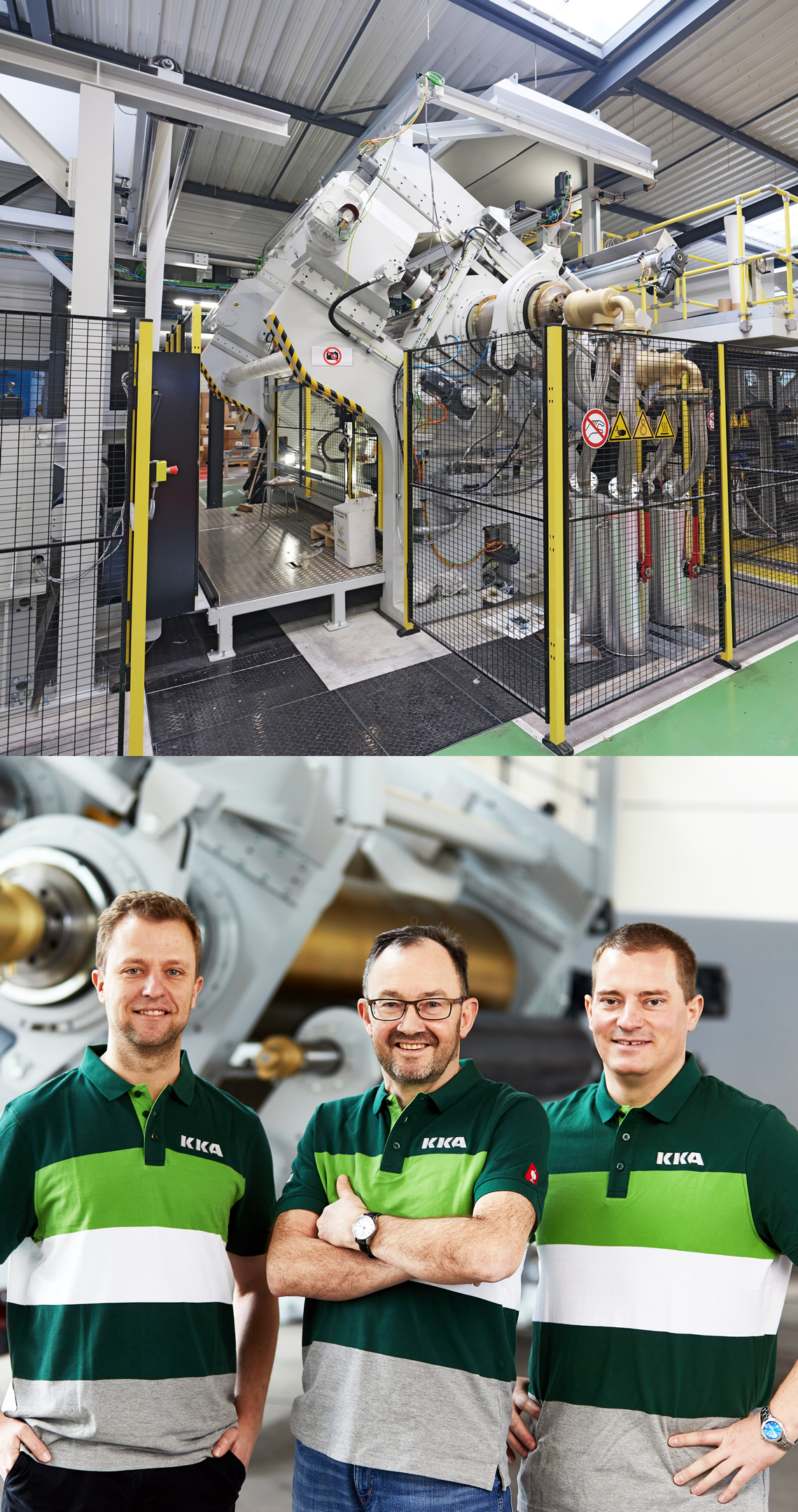

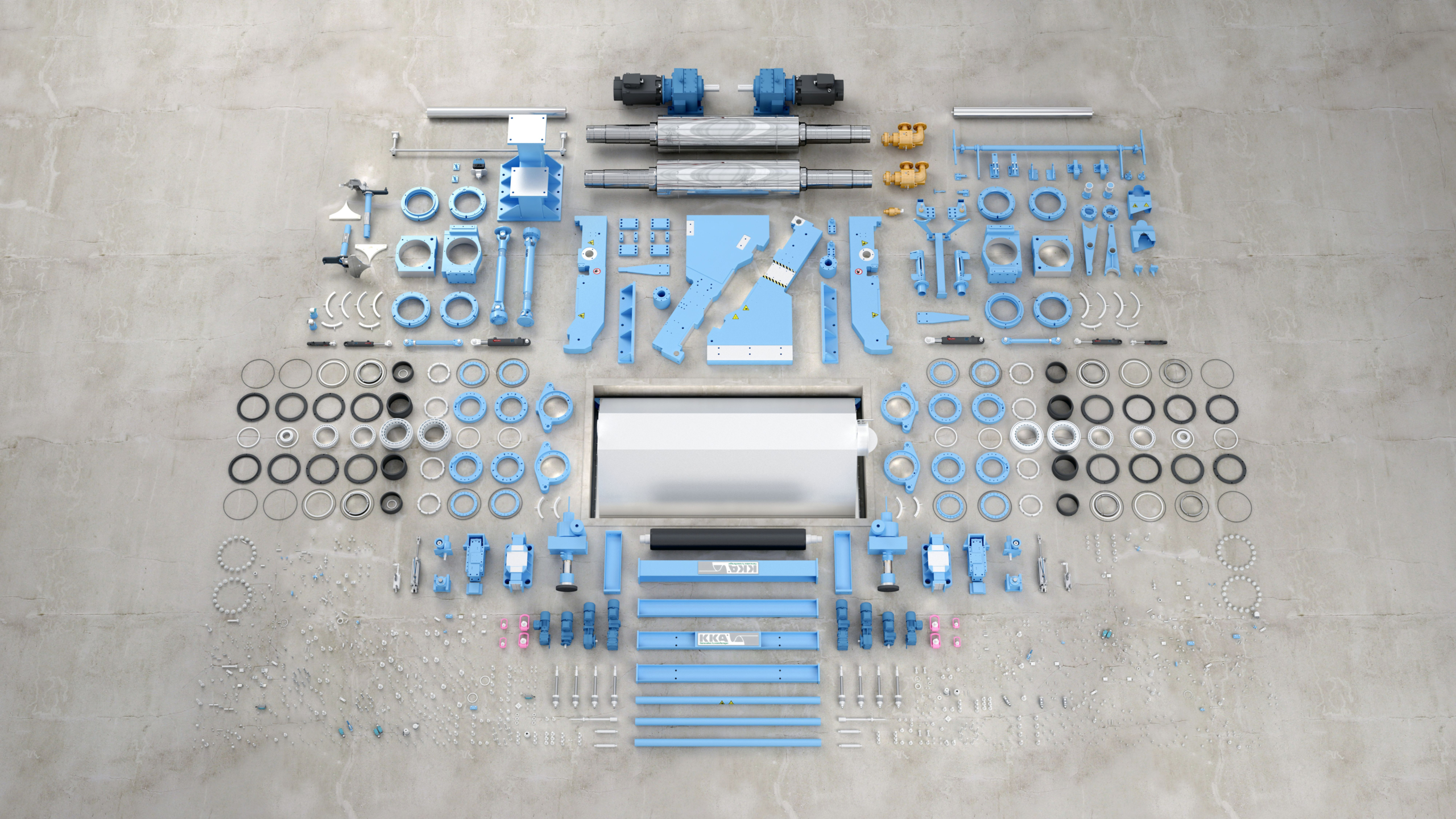

Together with its sister company SMBK, KKA has a staff of 75 employees and includes in addition to its own engineering department, control system department, production and four assembly shops where it is possible to assemble and commission lines that are up to 120 m long. Due to high vertical integration, a direct influence on all development and manufacturing steps is always assured. The following overview illustrates the diversity of our machinery and space availabilities.

Demands on progressive manufacturers have grown continually in recent years. We have been able to meet the increasing demands at our company group by resorting to state of the art production techniques in accordance with the quality standards of ISO 9001:2015. Qualified assembly teams as well as our own technical Know how in combination with a modern quality management guarantee a high standard in manufacturing and hence a high level of quality – „Made in Germany“.

World Wide

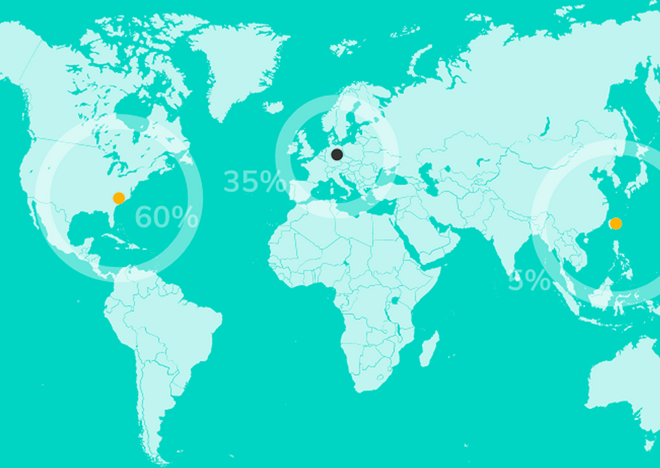

KKA is a global company. Due to the structural need for customized production lines, the main activities focus on the North American and Western European markets.

80% of the KKA plants are exported. Of this export share, deliveries to North America account for the largest share, at 60%. The system design refers to local regulations and standards. In any case the mechanical guidelines e.g. the OSHA are always considered as well as electrical regulations e.g. according to UL or other ones.

North America & Mexico

Representation

Fi-Tech, Inc.

2400 Pari Way

Midlothian, VA USA

www.fi-tech.com

Asia

Representation

Fruitive International Co. Ltd.

4F., No.15, Minyou 3rd St.,

Taoyuan City 33049, Taiwan

www.fruitive.com.tw