Coating

Coating is the most often used finishing process for web type materials. The industrial application field as well as the used coating tools and processes vary widely.

KKA coating machines and plants are used at the highest technological level to process functional materials in form of solutions, dispersions, emulsions, plastisols, polymer melt.

With many years of know-how and extensive experience in constructing coating plants we provide turn-key solutions from raw material processing to dosing into the coating tool.

In order to manufacture first-class products, high standards in plant technology are demanded and this also applies to surface finishing. KKA coating technology reflects an extensive experience and know-how in this field. Plant systems are consequently developed in accordance with the market requirements and technical progress.

Knife Coater

Offering flexible use, KKA knife coating machines also guarantee convincing coating results and can easily be adapted to very different production requirements. The main focus here is on efficiency and product quality. This type of coating lines can be used to manufacture a variety of products and widths of 500 to 5,500 mm.

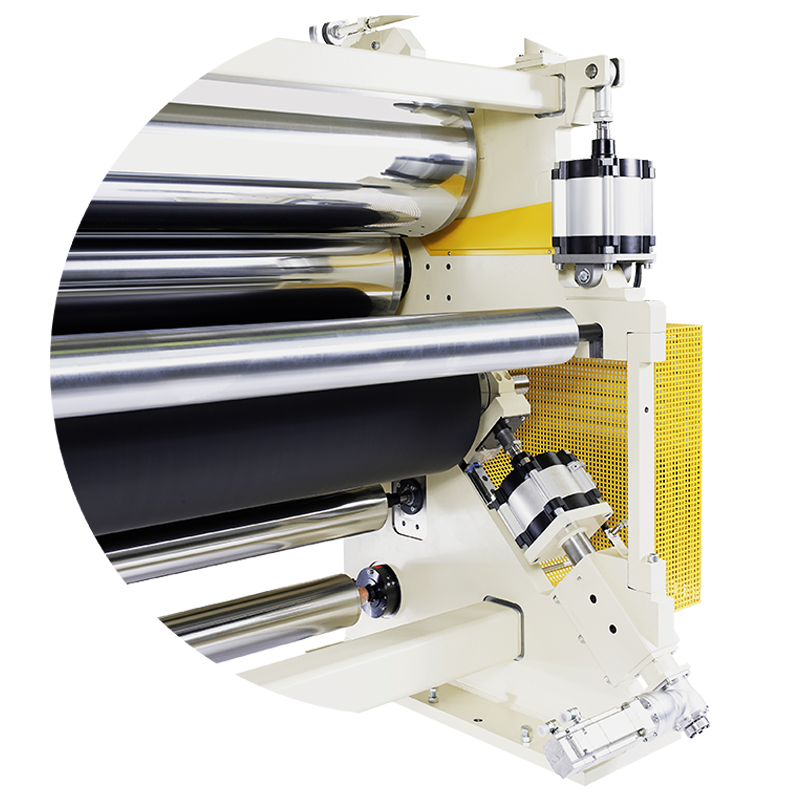

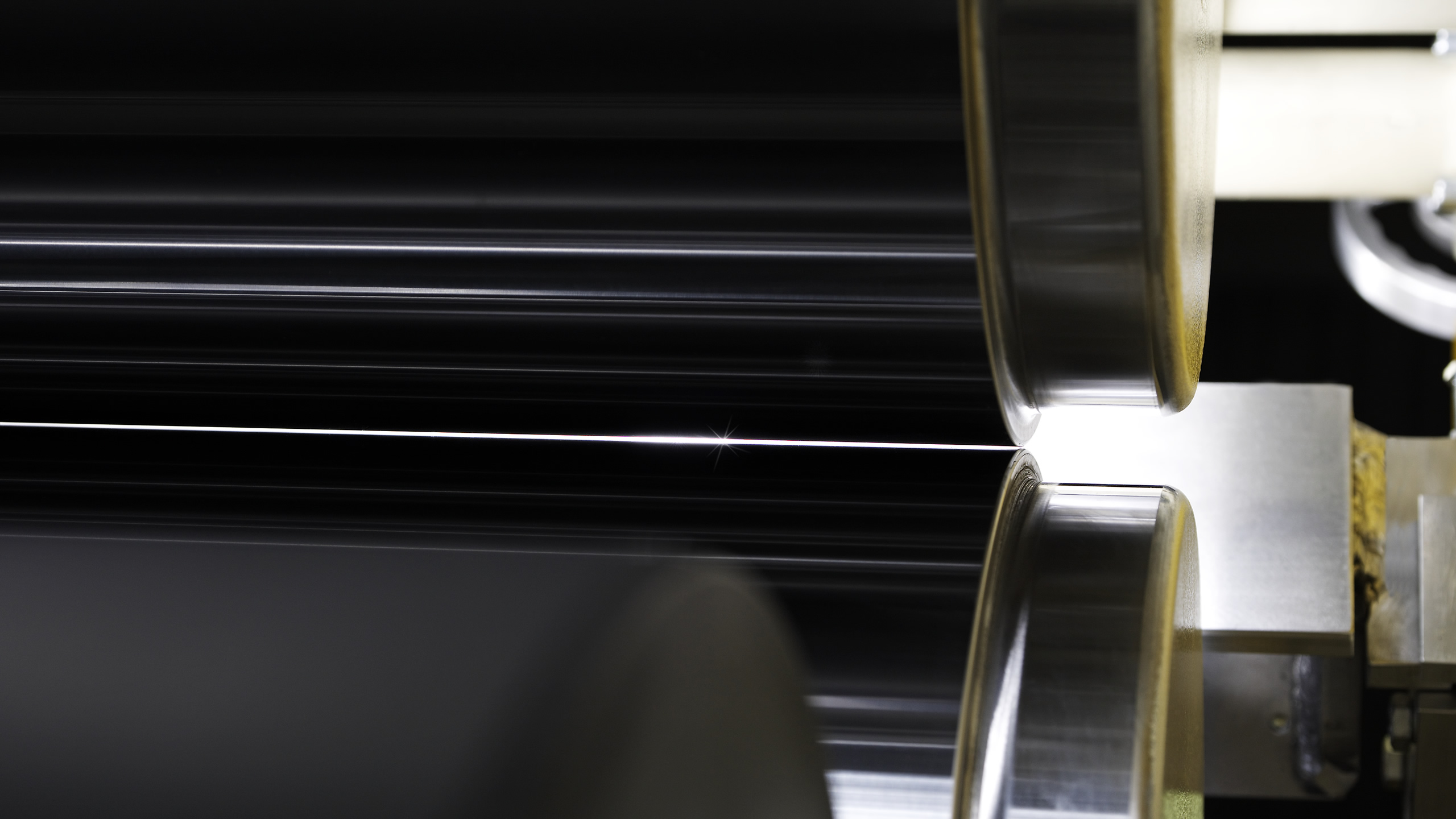

Reverse Roll Coater

KKA – Reverse-Roll-Coater achieves a uniformity of the application film independent of the tolerances of the coating carrier. Influencing the viscosity of thixotropic application media by varying the shear forces in the nip between dosing and application roller.

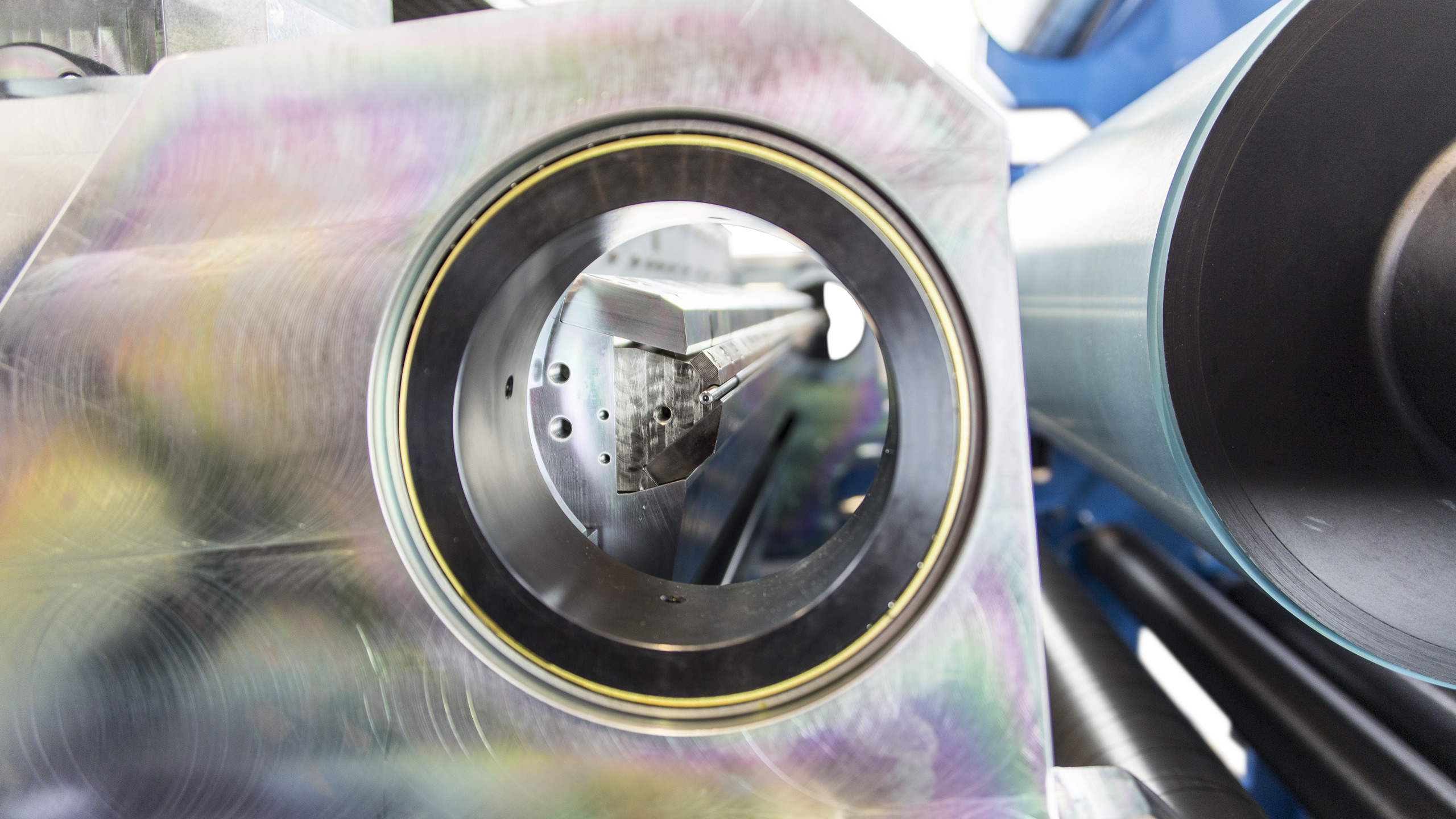

Slot Die Coater

Thanks to intensive cooperation with world-leading slot-die manufacturers, KKA is able to provide precise coating on a variety of substrates. The precisely designed peripherals such as bulk melters, refueling units, heated hoses, filter systems etc. complete the portfolio for the delivery of single coating units or complete lines.