Calender Coating

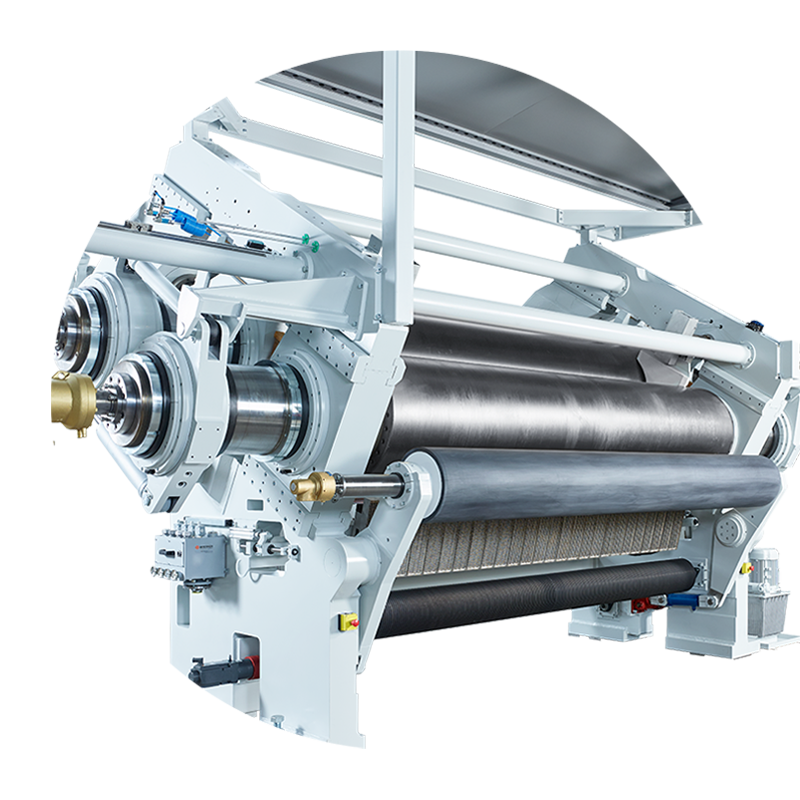

Calendering designates a process where rotating rollers are used to shape, calibrate and compress web type materials.

Polymer melts are processed in KKA calenders to produce mono-film without carrier and to directly laminate this film onto various web type substrates. Exactly tempered rollers with deflection compensation ensure high-precision nip geometries and guarantee first-class products based on polymer PVC, TPO, TPU. By combining KKA calender technology with extrusion tools, the field of application is extended to processing highly viscous melts and to producing materials with unique properties.

In order to manufacture first-class products, high standards in plant technology are demanded and this also applies to surface finishing.

KKA calendering technology reflects an extensive experience and know-how in this field.

Melt Roll Calender

Coating plants operating with melt rollers can be used to produce a variety of products and widths from 1,300 – 5,500 mm. The plants can be optionally equipped with 2- or 3-roller calenders. Application fields include coatings ranging from 80 to 2,000 g/m² using PVC, TPU, TPO (PP, PE), CPE, elastomers etc.

Extrusion

Thanks to intensive cooperation with world-leading slot-die manufacturers, KKA is able to provide precise coating on a variety of substrates. The precisely designed peripherals such as bulk melters, refueling units, heated hoses, filter systems etc. complete the portfolio for the delivery of single coating units or complete lines.